Technology

How does it work?

The ability of reliable, stable, and precise navigation is a core requirement for autonomous drone operations. From environmental sensing to precision landing to charging stations, every step has an important contribution in terms of operation.

Inspector Stock has several sensors and gathers the data coming from these sensors on an integrated processing unit. The redundancy principle is a key point during this calculation. A numerous safety function, against the case of sensor or communication loss, calculation errors or delays, etc., in the navigation core, has been integrated on the Inspector Stock drone in order to catch the highest possible accuracy without sacrificing robustness and safety.

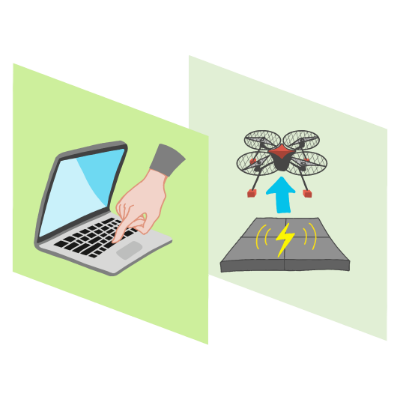

Fully Autonomous Operation

With a couple of clicks from control software, the drone counting system is ready for autonomous operation. By pressing the start button, all the commands are sent to the drone, and the operation commences. Communication between the control software and the drone is not important. After that point, all calculations are running over the drone and real time.

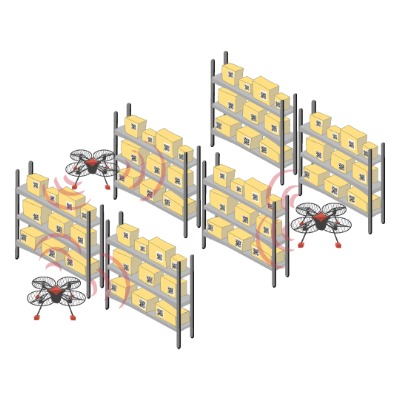

3D environmental Awareness

During the flight, onboard sensors gather data from the environment for efficient and safe operation. The warehouse layout is previously configured in the system. Any mismatch with the real environment will be detected during operation and reported.

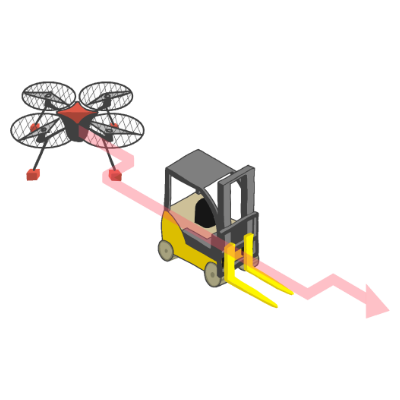

Collision Avoidance

The second step of environmental sensing is adoptive trajectory planning for active collision avoidance to increase the safety level. In case of any obstacles over the path, the obstacle will be detected and alternate routes will be calculated to complete the mission. The unfinished part of the operation will be reported later.

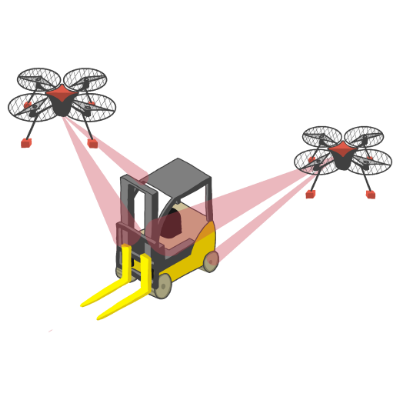

Swarm Operation

Because of present battery technologies, a single drone may not be sufficient for larger facilities. To make counting faster, Inspector Stock comprises swarm operation functions. Multiple flights at the same time will dramatically reduce counting duration.

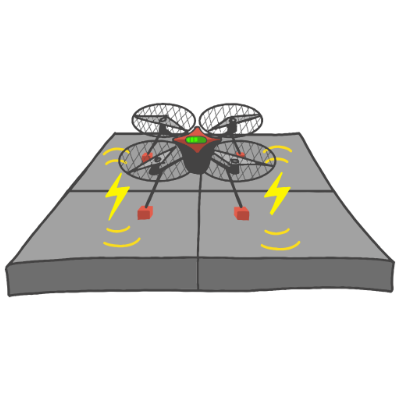

Auto-Charging Station

Another requirement of fully autonomous operations is an autonomous charging point. After every flight, the counting drones come back to charge themselves for the next operation. Charging points are pre-configured to the drones, and multiple drones in operation decide about which charging point is the most suitable.

Camera Based Detection

Every company has its specific label/barcode layout and product defining code. Some use barcodes, some others text or QR codes. Inspector Stock carries a high-resolution camera and illumination for a configurable system. Without any systematic change in the warehouse, the target label information will be extracted from the images taken from pallets. Additionally, empty & Full slot recognition, pallet, product type detection may be done if necessary.